Contemporary Embroidery Patterns to Try

Embroidery has evolved from traditional techniques to contemporary expressions of art and design. Today, it offers a fresh take on embellishing fabrics, providing a canvas for creativity and innovation. Whether you are a seasoned embroiderer or a curious beginner, this guide will introduce you to contemporary embroidery patterns that you can try, along with tips on techniques, styles, and inspiration.

1. What Are Contemporary Embroidery Patterns?

Defining Contemporary Embroidery

Contemporary embroidery patterns reflect modern aesthetics and innovative techniques, often blending traditional stitching with contemporary themes. These patterns can vary widely, incorporating bold colors, abstract shapes, and intricate designs. They celebrate individuality and self-expression, allowing artists to experiment with form and function.

Characteristics of Contemporary Patterns

Some common characteristics of contemporary embroidery patterns include:

Use of Color: Bright, vibrant colors that may not conform to traditional palettes.

Abstract Designs: Patterns that are more freeform and less rigid, often reflecting artistic styles such as minimalism or maximalism.

Mixed Media: Integration of other materials like beads, fabrics, and paper, enhancing the texture and visual interest of the embroidery.

2. Popular Contemporary Embroidery Styles

1. Minimalist Embroidery

Minimalist embroidery focuses on simplicity and clean lines. It often features small, understated designs that can be stitched quickly. Common motifs include geometric shapes, simple outlines, and single-color stitching. This style is perfect for those who appreciate a modern aesthetic without overwhelming details.

2. Abstract Art Embroidery

Inspired by abstract art, this style encourages creativity through freeform stitching. Abstract embroidery patterns may involve layering different stitches and colors to create dynamic visual effects. This style allows for complete artistic freedom, making it an excellent option for those who want to express their personality and style.

3. Nature-Inspired Designs

Contemporary embroidery often draws inspiration from nature, incorporating floral and botanical themes in fresh and unexpected ways. Patterns may feature oversized flowers, intricate leaf designs, or even abstract representations of landscapes. These designs can be colorful or monochromatic, adding a touch of nature to your fabric.

4. Typography and Text Embroidery

Embroidery has also embraced typography, with text-based designs becoming increasingly popular. This style involves stitching quotes, phrases, or even single words in creative fonts and layouts. The combination of text and stitching creates a personal touch, making it a favorite for home decor and gifts.

3. Tools and Materials for Contemporary Embroidery

Essential Tools

To get started with contemporary embroidery, you’ll need a few essential tools:

Embroidery Hoops: These keep your fabric taut while you stitch, ensuring clean and even work.

Needles: Use embroidery needles, which have a larger eye to accommodate thicker threads.

Fabric: Consider using a variety of fabrics such as cotton, linen, or even denim to enhance the texture of your designs.

Threads and Yarns

Experimenting with different types of threads can elevate your contemporary embroidery. Some options include:

Cotton Floss: Versatile and widely used in embroidery.

Metallic Threads: Add a touch of shine and glamour to your designs.

Wool and Specialty Yarns: Ideal for creating texture and depth in your patterns.

4. Step-by-Step: Creating Your Own Contemporary Embroidery Pattern

Step 1: Choose Your Design

Select a contemporary pattern that resonates with you. You can find inspiration from art, nature, or even online resources like Pinterest and Instagram. If you’re feeling creative, try sketching your design.

Step 2: Prepare Your Fabric

Iron your fabric to remove any wrinkles, and then secure it in an embroidery hoop. This will help keep the fabric taut as you work.

Step 3: Transfer the Design

Transfer your design onto the fabric using one of the following methods:

Tracing: Use a lightbox to trace your design directly onto the fabric with a fabric pencil.

Iron-On Transfer: Print your design on transfer paper and use an iron to adhere it to the fabric.

Freehand Drawing: For more artistic freedom, draw directly onto the fabric with fabric-safe markers.

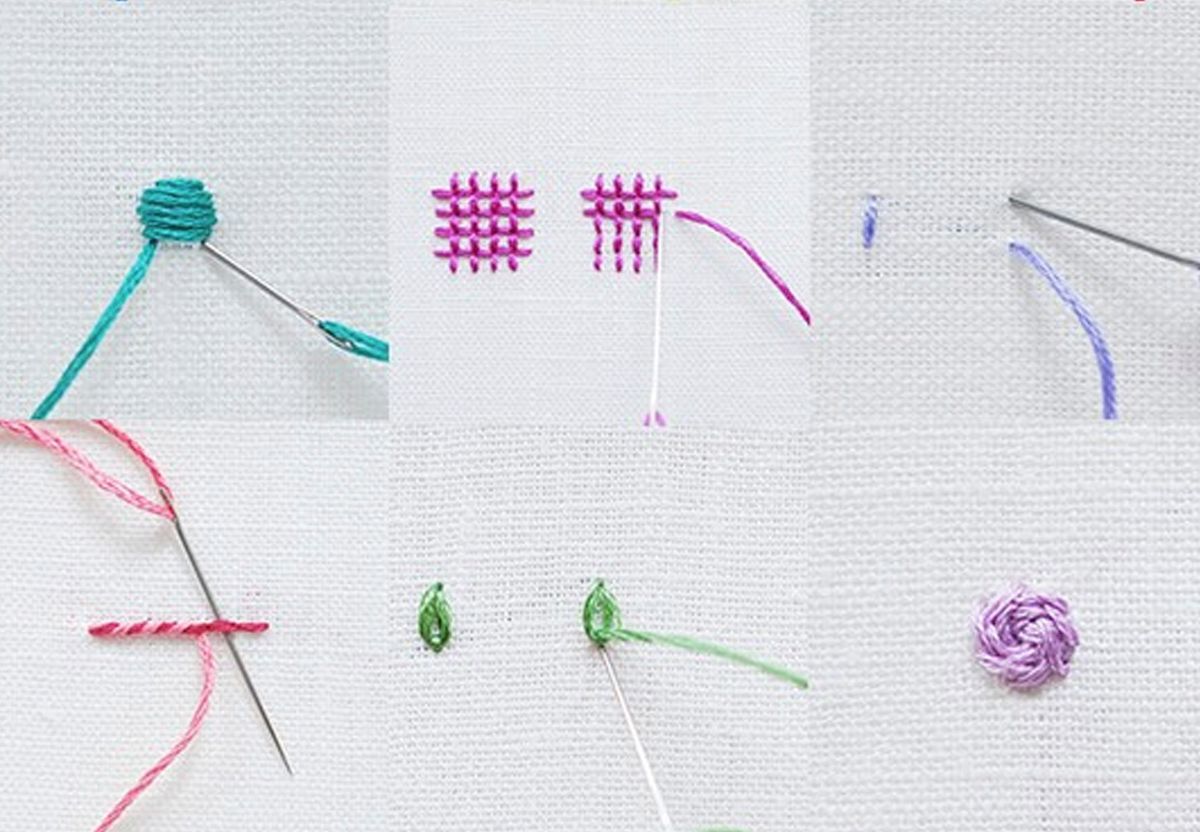

Step 4: Start Stitching

Begin stitching your design using a variety of stitches. Feel free to mix and match different stitches to achieve unique textures and effects. Don’t hesitate to experiment with colors and patterns as you go.

Step 5: Finishing Touches

Once you’ve completed your design, finish your embroidery by securing the threads at the back. You may want to frame your work or turn it into a functional item, like a bag or wall hanging.

5. Contemporary Embroidery Inspirations

Online Communities and Resources

Joining online embroidery communities can provide you with inspiration and support. Platforms like Instagram, Pinterest, and Facebook have dedicated groups and pages for embroidery enthusiasts. Follow contemporary embroidery artists to see their latest creations and gain new ideas for your projects.

Workshops and Classes

Consider taking part in workshops or classes to learn new techniques and meet fellow embroiderers. Many local craft stores and community centers offer courses focused on contemporary embroidery. These hands-on experiences can help you refine your skills and expand your creative horizons.

6. Tips for Mastering Contemporary Embroidery

Experiment and Play

Don’t be afraid to experiment with different stitches, materials, and techniques. Contemporary embroidery is about self-expression, so allow yourself to play and create without limits.

Incorporate Mixed Media

Combine embroidery with other art forms, such as painting, quilting, or collage, to create unique pieces. Mixed media can add depth and texture to your work, making it more visually engaging.

Document Your Journey

Keep a record of your projects, techniques, and patterns. Taking photos of your work can help you track your progress and inspire future designs. Consider creating a dedicated embroidery journal or blog to share your experiences and showcase your creativity.

Conclusion

Contemporary embroidery patterns offer a fantastic way to express creativity and explore new artistic avenues. By understanding the different styles and techniques, you can dive into this modern craft with confidence. Whether you’re creating minimalist designs or intricate abstract pieces, the world of contemporary embroidery is rich with possibilities. So gather your tools, choose a pattern that inspires you, and let your creativity shine through your stitching!